Sign in to your account using email and password provided during registration.

No products in the cart.

Upgrade your motors and pumps with our retrofitting services. We can deliver energy reduction through high-efficiency IE4&5 motor installations, enhanced reliability, and improved performance. Our solutions for pumps ensure compliance while driving down energy costs.

UPGRADE FOR ENERGY SAVING

RETROFITTING FOR EXPLOSION PROOFING

UPGRADE OF GENERATOR POWER

SIGNIFICANT SAVINGS, THROUGH FUNDAMENTAL CHANGES. MADE EASY.

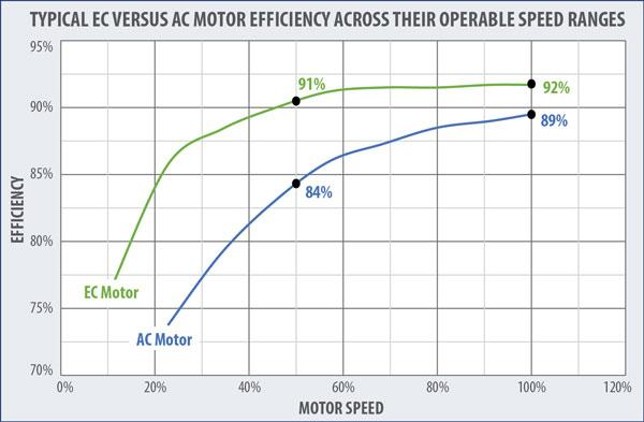

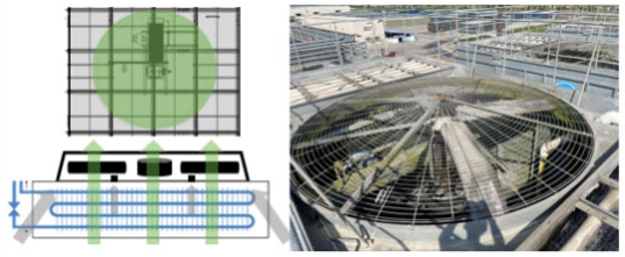

Replace (belt-driven) AC induction sets with high-efficiency EC fan modules for AHUs or cooling towers. Our retrofit combines a brushless permanent-magnet motor and integrated variable-speed drive, delivering required airflow and static pressure at lower power. Direct drive means no belts or pulleys—quieter operation and less maintenance.

Achieve upto 60% energy reduction from part-load control and higher motor efficiency. We handle survey, design, installation, commissioning—minimal disruption—and can add monitoring for ongoing tuning.

Cut consumption. Cut noise. Cut downtime.

TRANSMISSION–RELATED efficiency gains:

Typical energy savings:

EC Technology-related gains/losses:

Typical energy savings:

Speed Control-related gains/losses:

Typical energy savings:

Composition-related efficiency gains/losses:

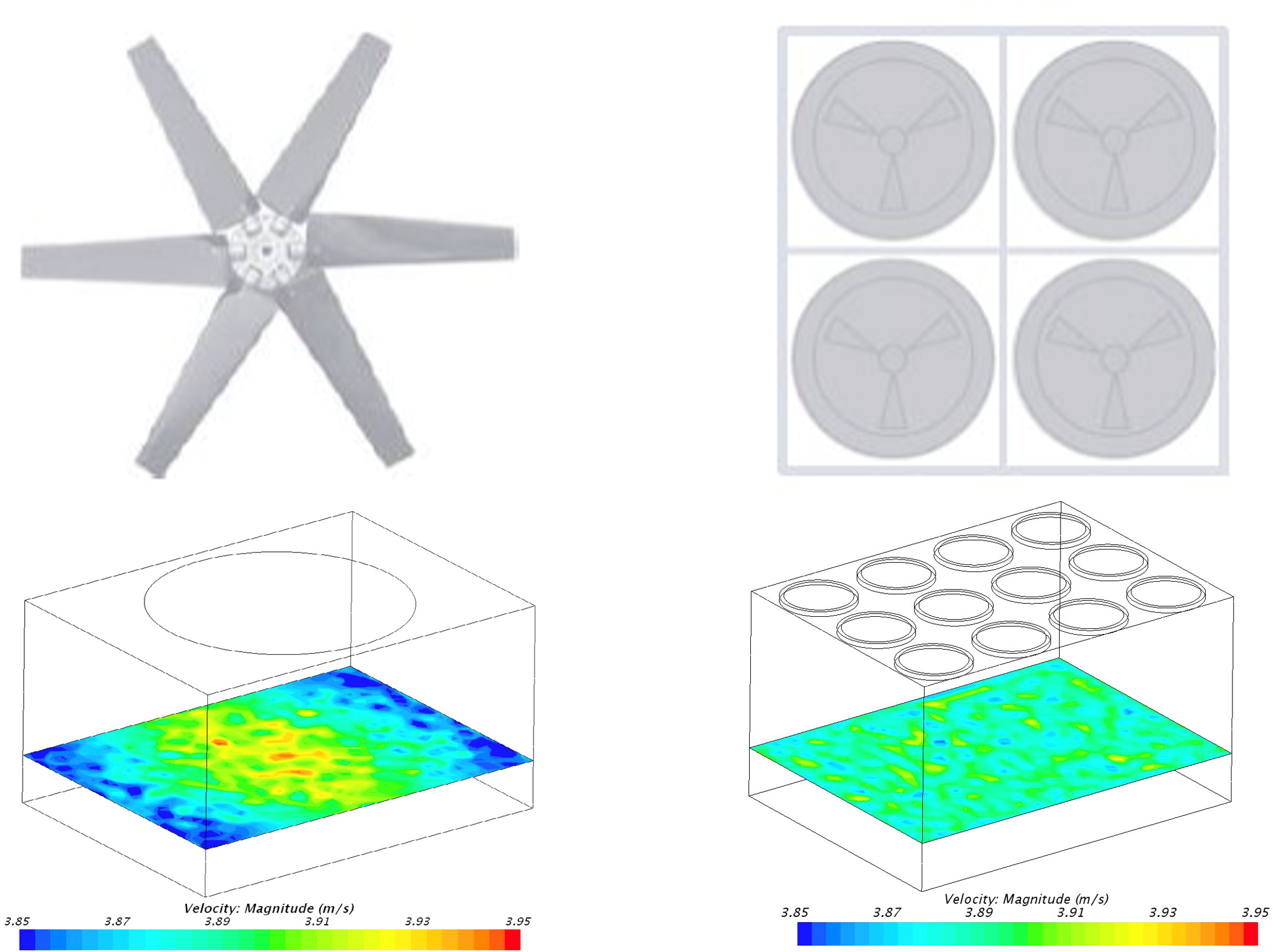

| Spesifikasi | Before Renovation | After Renovation |

|---|---|---|

| Impeller Diameter | 2100mm | 990 mm |

| Voltage | 400 VAC | |

| Power | 7.8 kW | 1.318 kW x 4 = 5.27 kW |

| Current | 33.73 A | 2.1 A x 4 = 8.4 A |

| Speed | 1,469 rpm | 760 rpm |

| Airflow | 51,200 cfm | |

| Static Pressure | 100 Pa | |

Contact us today to learn how our smart lifecycle management solutions can

transform your operations

COMPREHENSIVE EXPLOSION

PROTECTION UPGRADE SERVICES

Engineered solutions for converting systems to positive pressure explosion-proof designs, including full EPC implementation.

APPLICATIONS: WHAT

Petroleum, petrochemical, and chemical sites. Enhances explosion-proof performance of electrical equipment, whether originally designed as explosion-proof or not.

SYSTEM ELEMENTS: HOW

The system incorporates motor explosion-proof sealing modification, explosion-proof fans, valves, pipelines, transmitters, control cabinets, and a pressure measurement and control system.

TECHNICAL ADVANTAGES: WHY (US)

Deep expertise in positive pressure explosion-proof motor principles. Systematic experience in both single machine and comprehensive system modifications. Third-party quality verification.

UPGRADES OF EXPLOSION-PROOF MOTORS

UPGRADES OF NON-EXPLOSION PROOF MOTORS

CASE STUDY:

CASE STUDY: RETROFITTING FOR EXPLOSION PROOFING

Contact us today to learn how our smart lifecycle management solutions can

transform your operations

OVERHAUL AND REBUILD SYSTEM SOLUTIONS:

1) Generator capacity upgrade

2) Transformation system solutions

APPLICATIONS: WHAT

1) Generator power upgrade solutions for energy recovery systems (biomass, waste heat/pressure, and waste power generation).

2) Transformation projects in power generation systems (steel, metallurgy, and waste power plants).

SYSTEM ELEMENTS: HOW

Our system upgrades include generators, excitation control cabinets, synchronization cabinets, PT cabinets, neutral point cabinets, and oil stations

TECHNICAL ADVANTAGES: WHY (US)

Our generators utilize British PPI box-type technology and incorporate seven of our company’s utility model patents. We have a complete manufacturing and supply system, demonstrated by the reliable operation of over 2,000 generators.

Contact us today to learn how our smart lifecycle management solutions can

transform your operations